- Home

-

Product

-

Electric Power Equipment

能效變壓器 Power Transformer Distribution Transformer Dry-type Transformer Compact Substation 成套設(shè)備 -

Power Internet of things

Substation Operation Monitoring Platform Wisdom Park Power Service Cloud Platform Safe Electricity Platform Asset Management Integrated Energy Management Platform -

Electricity Service

Substation Operation Service Electric Power Maintenance Power Emergency Repair -

電力科技

SVG 無(wú)功補(bǔ)償產(chǎn)品 APF 10KV配電線路 -

Electric Power Design

Transmission Line Design Power Distribution Design -

Power Engineering

Equipment Handover Test Distribution Cable Laying Distribution Civil Engineering Project

-

- Solution

-

Services

Create a team with excellent achievements, share with employees the result of enterprise development.

To learn more

- News

-

About

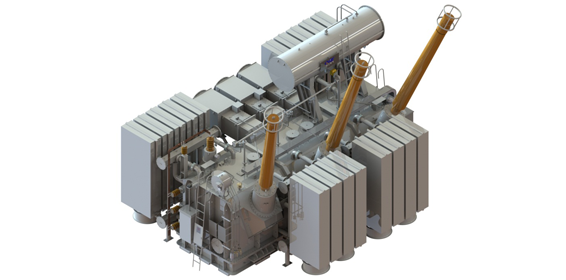

330kV Power Transformer

330kV Series Oil-immersed Power Transformer